Tech

Revolutionizing Magnesium Extraction with MagCXTM

Our MagCXTM process—a patented, groundbreaking method for extracting Magnesium with exceptional purity while leveraging abundant U.S.-based mineral resources.

The Critical Need for Magnesium

Magnesium plays a vital role in advancing industries, however the U.S. remains heavily reliant on foreign sources, leaving critical industries vulnerable to disruption. It’s unique properties make it indispensable.

Lightweight & Strong

Magnesium is 75% lighter than steel and 35% lighter than aluminum, providing unmatched weight reduction in structural applications.

Superior Versatility

Magnesium offers high damping capacity (energy absorption), heat dissipation, and shock absorption, making it ideal for demanding environments.

Sustainability

Magnesium is 100% recyclable, aligning with the push for greener, more sustainable manufacturing processes.

The MagCXTM Advantage

The MagCXTM process is a revolutionary advancement in Magnesium extraction, which offers:

Unparalleled Purity

Producing Magnesium with purity levels exceeding 99%.

Domestic Reliance

Utilizing readily available U.S. mineral ores to reduce dependency on foreign suppliers.

Energy Efficiency

Designed for cost-effective production while minimizing environmental impact.

How It Works

By leveraging readily available U.S. mineral ores, our process ensures sustainable, cost-effective, and high-grade Magnesium production.

Raw Material Sourcing

Abundant domestic mineral resources serve as the foundation for Magnesium production.

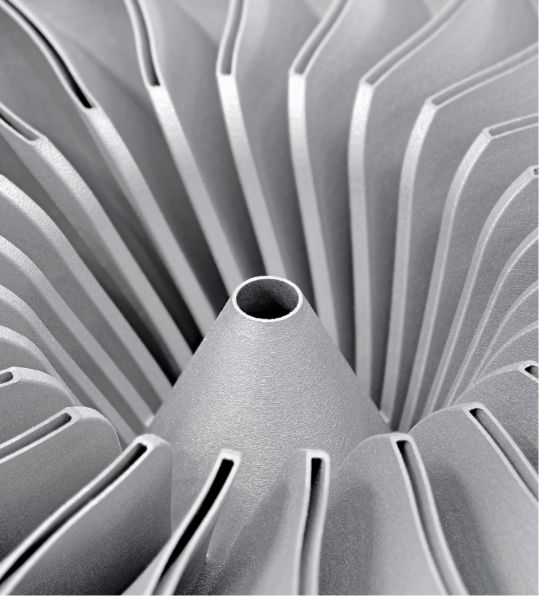

Reduction Chamber

Abundant domestic mineral resources serve as the foundation for Magnesium production.

High-Grade Output

The result is high-purity Magnesium ready for use in diverse industries.

Applications of Magnesium

Magnesium’s versatility makes it a critical material in industries that demand innovation and performance.